-

Biotherapeutics

Advancing patient care with biologics: 4 ways Mayo Clinic’s biomanufacturing strategy is making a difference

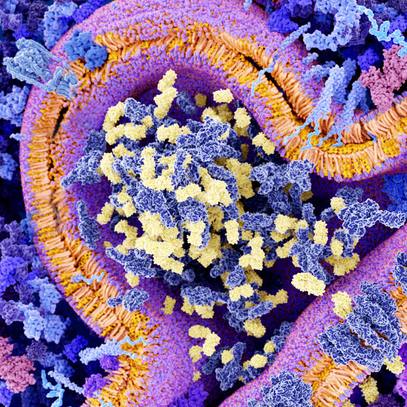

Mayo Clinic seeks to harness the power of cells, tissue and genes by delivering first-of-their kind therapeutics for patients in early-stage clinical trials. Mayo Clinic's Center for Regenerative Biotherapeutics is leading an effort that is at the crossroads of biology, engineering, industry and medicine to expand biomanufacturing for rare and complex disorders. Biomanufacturing is the use of living organisms such as cells in the manufacturing of new medicines.

On-site biomanufacturing helps Mayo Clinic validate new biologics in clinical trials, which aim to benefit patients in at least four ways:

- Addressing the unmet needs of patients

Mayo Clinic is driven by the needs of the patient. Innovative new therapies often originate from physician-scientist research teams who are seeking new treatments for complex conditions such as diabetes, kidney failure or cancer.

"With most of the diseases we are researching, there is no therapy available for the patient, or the care that is available is not effective," says Julie Allickson, Ph.D., the Michael S. and Mary Sue Shannon Director of the Mayo Clinic Center for Regenerative Biotherapeutics. "Our goal is to advance cell and gene therapies that go beyond treating symptoms to cure patients. Our hope is to improve quality of life."

Dr. Allickson is also the Otto Bremer Trust Director, Biomanufacturing and Product Development, Center for Regenerative Biotherapeutics.

Examples of biologics — medicines from human sources such as blood, cells, genes and tissue — are immunotherapies to kill blood cancers and an experimental, cell-based vaccine to stop the spread of ovarian cancer.

- Accelerating the most promising discoveries to patient care

Biomanufacturing provides a bridge that transitions promising discoveries from the lab to first-in-human clinical trials. The goal is to advance technologies that would have broad clinical use for all patients who need them.

"We're manufacturing medicines that we hope will transfer seamlessly to commercial markets," says Cynthia Wilkins, Ph.D., senior director of process development in the Center for Regenerative Biotherapeutics. "Working with industry can provide the support needed to move new medicines forward.'"

After validating biotherapeutics in phase 1 or 2 clinical trials, Mayo Clinic wants to license the technology to industry collaborators. From there, those licensees could advance the new drugs to regulatory approval and clinical care for patients around the world.

- Increasing collaboration and innovation

Mayo Clinic is expanding its Current Good Manufacturing Practice (CGMP) facilities to manufacture experimental medicines on all its campuses. CGMP facilities are clean rooms where drugs are manufactured in aseptic (free of contamination) environments that meet Food and Drug Administration specifications for safety, identity, strength, purity and quality.

With on-site facilities, Mayo's biomanufacturing team can work side by side with researchers to address problems quickly and find innovative solutions. On-site manufacturing capabilities also may enable Mayo to circumvent scheduling backlogs and delays that may occur with external contract manufacturers.

"This collaboration gives us immediate feedback on how the biomanufacturing process is progressing. That helps us respond to issues quicker," says Snigdha Rai, Ph.D., senior director of advanced biomanufacturing for the Center for Regenerative Biotherapeutics. "If we can troubleshoot quicker and more effectively, then we can get the therapeutic to patients sooner. We want to avoid situations in which we find a problem at the final manufacturing stage and need to start over."

Mayo Clinic has established a robust biomanufacturing structure that includes process development, quality control and quality assurance to ensure a drug has consistent quality once it is scaled up for production.

"On-site collaboration helps ensure we are not deviating from what the investigator wants. If a change is needed in process development, we are able to connect immediately with the investigator," says Dr. Wilkins. "If we're having challenges transferring the discovery to biomanufacturing, we can readily communicate with the investigator and ask, 'What do you know that can help us fix the problem?'"

- Applying a 3-shield approach to new therapeutics

A unique advantage of biomanufacturing at Mayo Clinic is the immediate application it has to patients participating in a wide variety of clinical trials. Physicians work with the biomanufacturing team to help them understand how the process can be shaped to meet the needs of those patients.

"Mayo's approach breaks down the silos. By working directly with physicians, we get to see a variety of medicines for many different types of diseases. That's very exciting. It's different from some other organizations in which the operational side does not interact with the clinical side," says Rai. "That inspires hope we can deliver lifesaving therapies for patients in need of new options."

Education is another critical component that Mayo Clinic integrates into its biomanufacturing strategy. Mayo Clinic Graduate School of Biomedical Sciences is one of the first to offer a doctorate in regenerative sciences with coursework in biomanufacturing for future physicians, scientists and allied health staff.

Biomanufacturing is regulated and complex. The deep collaboration with scientists and physicians across research, education and the practice has uniquely positioned Mayo to advance new biologic therapies for unmet patient needs.

###